Other LPG Equipments

BY-PASS VALVE

By-Pass Valve is one of the most important component for the LPG and anhydraous ammonia handling applications. Because on liquefied gas systems, an external bypass valve, piped back to the supply tank, is necessary for maximum pump performance and longer pump life. The by-pass valves can be setted between 0-216 psi (0-15 bar). The bypass valve will automatically prevent excessive pressure resulting from accidental pump overspeeding, discharge shut-off, or highly restrictive receiving systems.

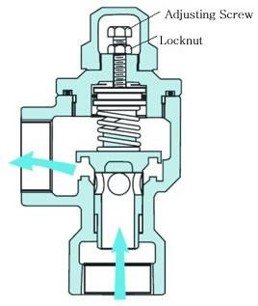

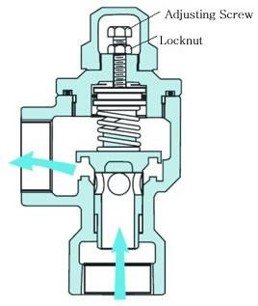

WORKING PRINCIPLE

Fluid forces to open the poppet of the by-pass valve as the pressure raises in the discharge pipeline instantly. If the pressure raised greater than the setting pressure, pressurized spring lets the poppet to open and start by-pass circulation. Fluid returns into feed tank. Circulation over a long period of time through the by-pass valve causes a significant heating up.

| BY-PASS MODEL AND FEATURES | ||||

|---|---|---|---|---|

| By-Pass Model | Inlet/Outlet Size | Max. Working Pressure | ||

| Inch | Mm | PSI | Bar | |

| 1″ Threaded | 1″ | 25 | 360 | 25 |

| 1 ½” Threaded | 1 ½” | 40 | ||

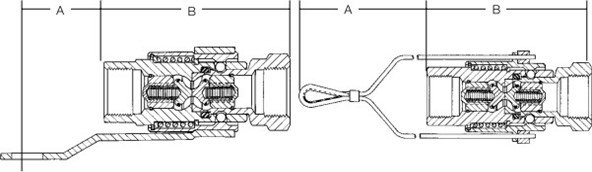

LPG BREAKAWAY (PULL-AWAY) COUPLING

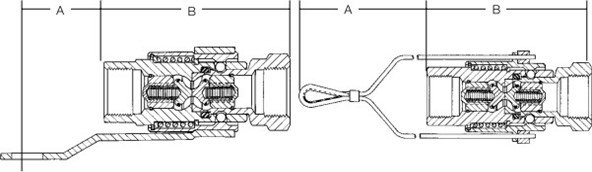

LPG Series Breakaway Couplings provide breakaway protection for LPG transfer operations. If the vehicle drives away with the nozzle connected, LPG Breakaway Coupling allows seperation and provides efficieny and safety for accidents. In the event of pull-away, an excessive tension causes the coupling to seperate automatically, closing both two internal back pressure poppet checks. Materials- Body: Cadmium Plated Steel & Brass

- Seals: Buna-N Rubber

- Cables: Nylon Coated, Galvanized Steel

| TECHNICAL SPECIFICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Part Number | Inlet/Outlet Connections | Disconnect Force (kg) | Reconnect Force (kg) | Length of Valve | LPG Liquid Flow Capacity (l/min) | |||

| 5 PSIG | 10 PSIG | 25 PSIG | 50 PSIG | |||||

| FLC250 | 3/4″ | 59 | 36 | 3 7/8″ | 50 | 72.7 | 113.7 | 163.7 |

| FLC260 | 1″ | 34 | 23 | 4 9/16″ | 95.5 | 136.5 | 213.7 | 304.6 |

| FLC270 | 1 1/4″ | 72.5 | 11.5 | 5 5/8″ | 236.4 | 341 | 545.5 | 772.8 |

| FLC290 | 2″ | 136 | 23 | 14 5/16″ | 1137 | 1591 | 2500 | 3410 |

LPG DISPENSER HOSE

LPG hose provides excellent service across a wide variety of industrial and commercial LPG/propane delivery and supply applications. The flexible industrial rubber hose is available in long continuous lengths for efficient delivery/supply and maximum utility at job sites where the gas source might be a significant distance from the application. Features- Flexible and light weight

- Excellent bending radius.

- Very good cover resistance.

- Operating Pressure: 0-25 bar

- Explosion Pressure: 50 bar

- Hose Diameter: 1/2″ – 5/8″

- Hose Lenght: 4m / 4,5m / 5m

- Contact Measure: 3/4″ NPT 1″

- Temperature Range : -30 C° to + 70 C°

- Dissipation of static electricity ensured by the tube and bonding braid.

BY-PASS VALVE

By-Pass Valve is one of the most important component for the LPG and anhydraous ammonia handling applications. Because on liquefied gas systems, an external bypass valve, piped back to the supply tank, is necessary for maximum pump performance and longer pump life. The by-pass valves can be setted between 0-216 psi (0-15 bar). The bypass valve will automatically prevent excessive pressure resulting from accidental pump overspeeding, discharge shut-off, or highly restrictive receiving systems.

Fluid forces to open the poppet of the by-pass valve as the pressure raises in the discharge pipeline instantly. If the pressure raised greater than the setting pressure, pressurized spring lets the poppet to open and start by-pass circulation. Fluid returns into feed tank. Circulation over a long period of time through the by-pass valve causes a significant heating up.

| BY-PASS MODEL AND FEATURES | ||||

|---|---|---|---|---|

| By-Pass Model | Inlet/Outlet Size | Max. Working Pressure | ||

| Inch | Mm | PSI | Bar | |

| 1″ Threaded | 1″ | 25 | 360 | 25 |

| 1 ½” Threaded | 1 ½” | 40 | ||

LPG BREAKAWAY (PULL-AWAY) COUPLING

LPG Series Breakaway Couplings provide breakaway protection for LPG transfer operations. If the vehicle drives away with the nozzle connected, LPG Breakaway Coupling allows seperation and provides efficieny and safety for accidents. In the event of pull-away, an excessive tension causes the coupling to seperate automatically, closing both two internal back pressure poppet checks. Materials- Body: Cadmium Plated Steel & Brass

- Seals: Buna-N Rubber

- Cables: Nylon Coated, Galvanized Steel

| TECHNICAL SPECIFICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Part Number | Inlet/Outlet Connections | Disconnect Force (kg) | Reconnect Force (kg) | Length of Valve | LPG Liquid Flow Capacity (l/min) | |||

| 5 PSIG | 10 PSIG | 25 PSIG | 50 PSIG | |||||

| FLC250 | 3/4″ | 59 | 36 | 3 7/8″ | 50 | 72.7 | 113.7 | 163.7 |

| FLC260 | 1″ | 34 | 23 | 4 9/16″ | 95.5 | 136.5 | 213.7 | 304.6 |

| FLC270 | 1 1/4″ | 72.5 | 11.5 | 5 5/8″ | 236.4 | 341 | 545.5 | 772.8 |

| FLC290 | 2″ | 136 | 23 | 14 5/16″ | 1137 | 1591 | 2500 | 3410 |

LPG DISPENSER HOSE

LPG hose provides excellent service across a wide variety of industrial and commercial LPG/propane delivery and supply applications. The flexible industrial rubber hose is available in long continuous lengths for efficient delivery/supply and maximum utility at job sites where the gas source might be a significant distance from the application. Features- Flexible and light weight

- Excellent bending radius.

- Very good cover resistance.

- Operating Pressure: 0-25 bar

- Explosion Pressure: 50 bar

- Hose Diameter: 1/2″ – 5/8″

- Hose Lenght: 4m / 4,5m / 5m

- Contact Measure: 3/4″ NPT 1″

- Temperature Range : -30 C° to + 70 C°

- Dissipation of static electricity ensured by the tube and bonding braid.